Inventory management from the cloud with optimal and efficient order picking. Real-time insight into stock levels and order statuses for both you and your customers.

One flexible solution, tailored to your unique working method.

Different clients use different methods in their processes. Whether it concerns registering serial numbers, storing stock with batch codes or performing VAS activities during order picking; every client has unique needs. All these processes can be designed in Babeldat; without programming!

Discover our features

All events within Babeldat are extensively recorded in the event log, so that there is control over the actions performed in the WMS at all times.

Purchase

Monitoring and processing purchase orders from clients.

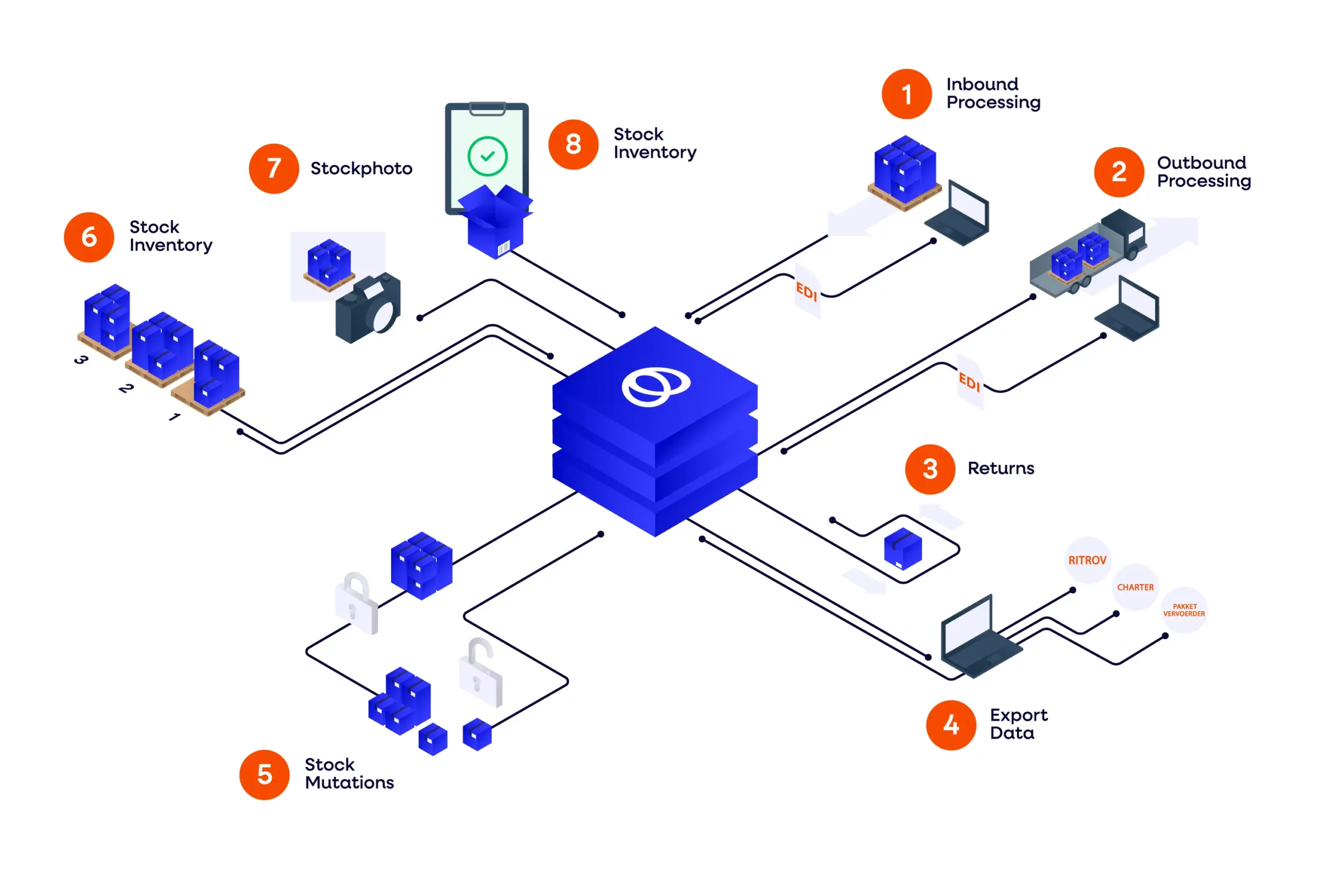

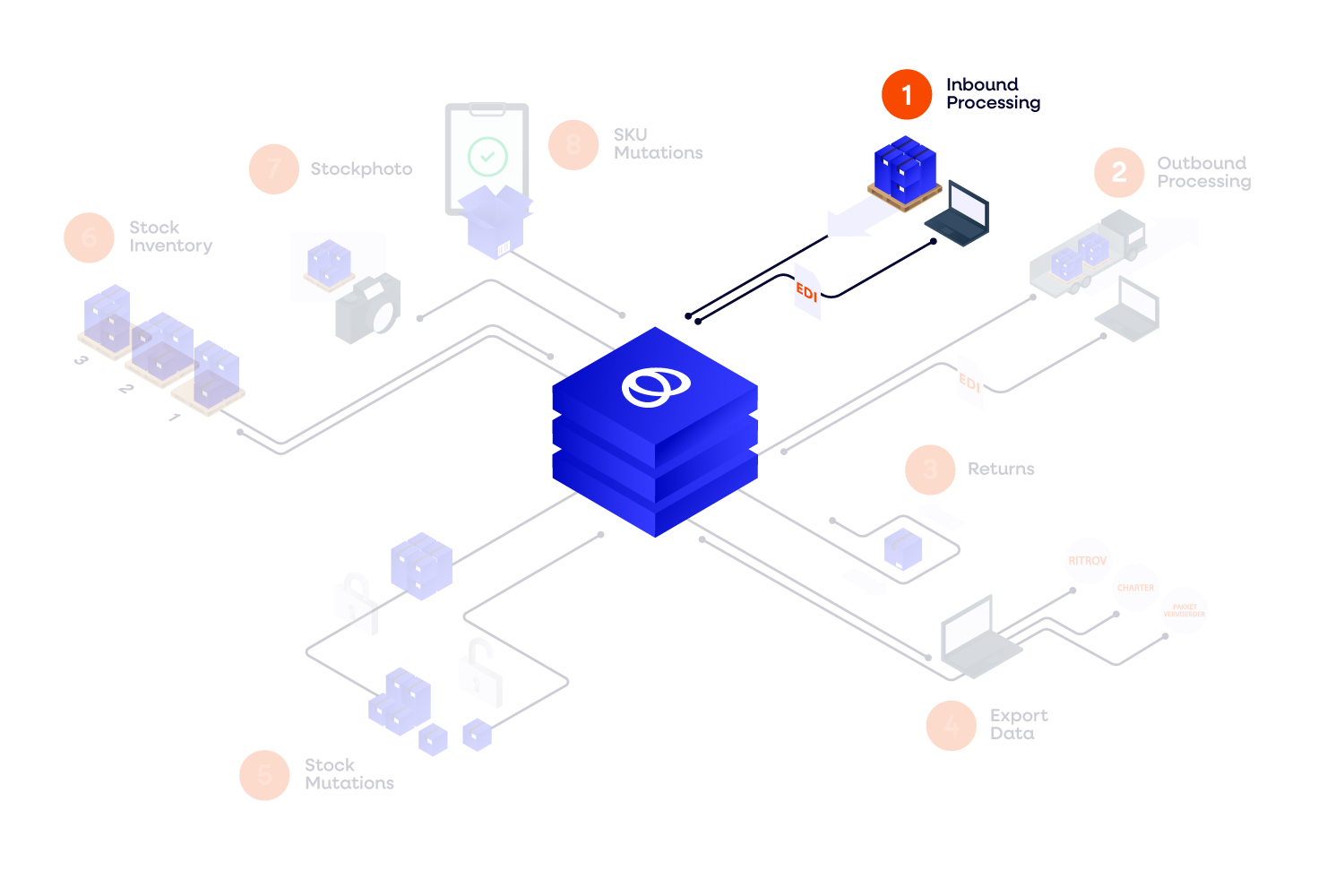

Inbound

Checking and processing goods delivered at the warehouse. Including stock mutations.

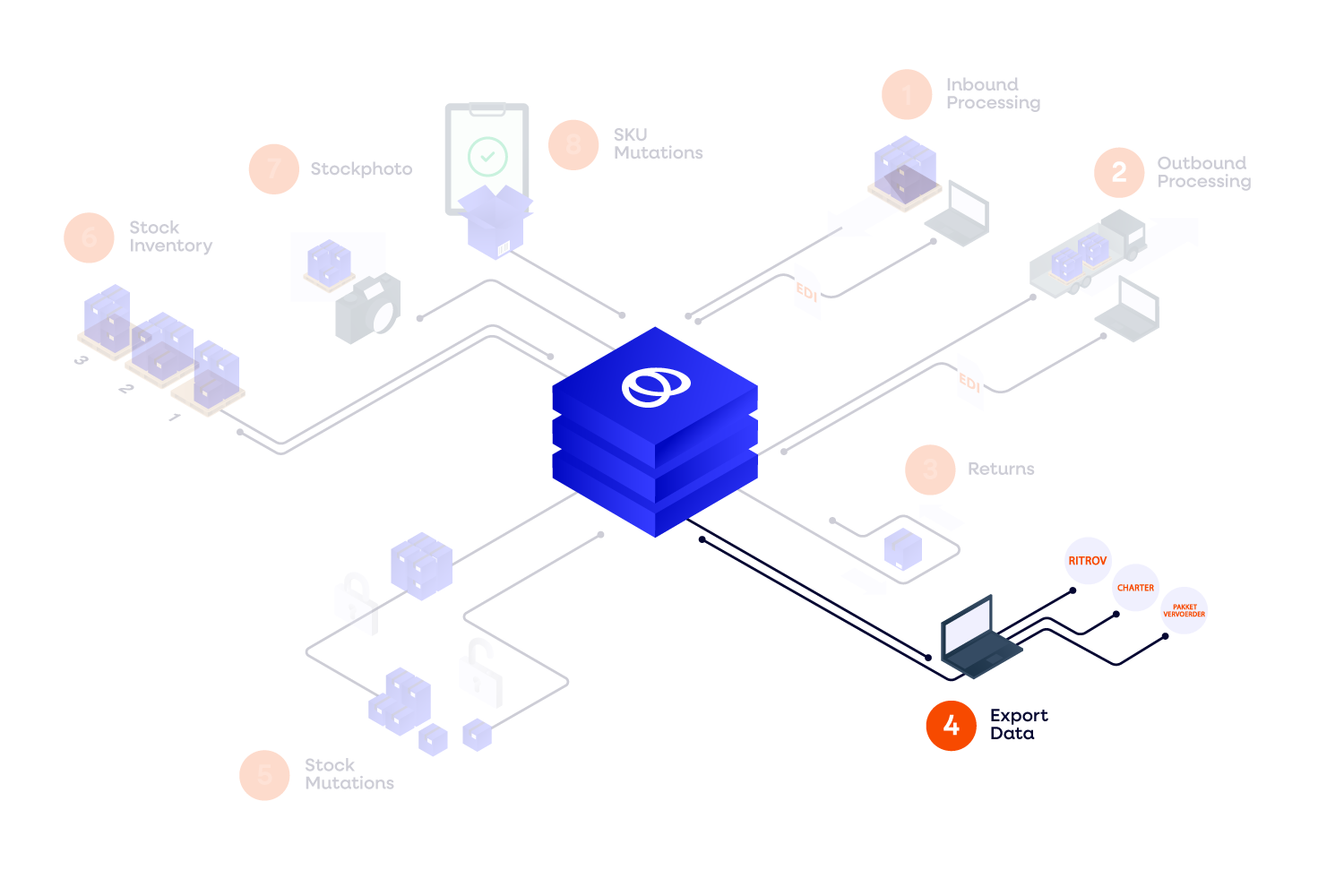

Outbound

Scanner controlled order picking, processing orders and reporting to clients.

Warehouse

Scanner controlled order picking, processing orders and reporting to clients.

Invoicing

Automatic or manual generation of invoice lines related to warehousing.

The benefits of Babeldat

Inventory Management

Inventory Management

Easily manage stock for different clients.

Flexibility

Flexibility

Individual processes can be set up by setting client-specific criteria.

Order processing

Order processing

Flexibility in adding necessary information to orders and items using attributes.

Locations

Locations

Ability to manage inventory at different locations.

Integrations

Integrations

Data exchange between systems with self-configurable import mappings and export layouts.

Connection to TMS

Connection to TMS

Forward outbound orders from the warehouse to transport planning in one action.

Receive goods in a controlled and streamlined manner.

Inbound orders can be created from an ‘order’ basis, as purchase orders can come in throughout the year and consist of several inbound orders. Babeldat offers the possibility to clearly keep track of what has and has not been delivered via an ‘order’, in order to maintain control over the final purchase order. In addition, we carefully check and register upon arrival (optional) for the correct batch code, best before date, quantity and of course the item code.

Regular inboundorders

All required data at order and product level are known when the order is registered and can be checked upon receipt of goods.

Inboundorder without restrictions

If it is not yet completely clear which items and quantities will be received, you can work with a free scan. Through this method, all delivered goods can be stored and the stock can be managed correctly.

Traceability

When creating stock mutations, each pallet is provided with a unique load carrier number, on which the goods can be traced during internal stock movements and for picking orders.

Efficient order picking and accurate outbound registration.

Goods can be picked and shipped at both pallet and package level.

When picking individual packages, a new load carrier can be created on which the items are registered immediately during picking. During order picking, the load carrier can be immediately provided with the correct labels, for example using a mobile printer. For additional control, the shipment can be rescanned and checked at a packing table before the packing slip is printed. The layout of the packing slip can be adjusted per customer (or even per recipient), so that all parties involved are provided with the information most relevant to them. Order picking can be performed using barcode scanners, an Android device, or through paper picking lists.

The outbound order is automatically generated based on customer-specific picking priorities and the desired walking route can be determined.

FIFO

First In, First Out. Items are picked in the order they were received, with the oldest items being picked first.

LIFO

Last In, First Out. Items are picked starting with the most recently received items, prioritizing the newest inventory.

Best before date

Items are picked based on their expiration or best before dates to ensure freshness or quality.

Location

tems are picked based on their physical storage location within the warehouse or facility.

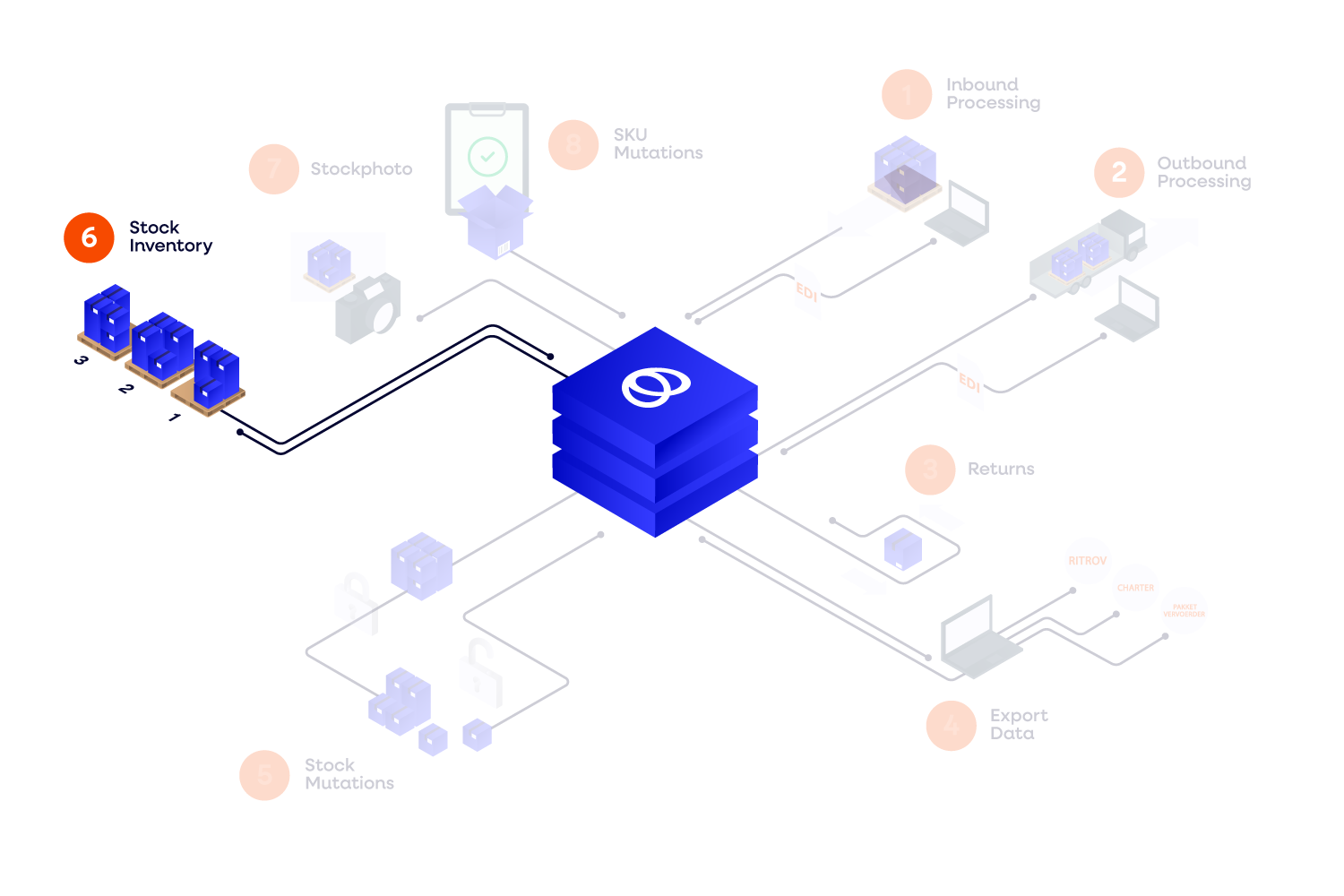

Simple but detailed inventory management.

Each SKU (Stock Keeping Unit) is stored in the warehouse on the smallest delivery unit. Each SKU is assigned to a load carrier, which in turn is registered at a specific location within the warehouse. This location is connected to a warehouse, which is located at a specific site or branch.

In addition, it is possible to bundle products, which contributes to simplified and efficient inventory management.

Item details

The stock data includes the quantity, batch code, serial number, expiration date, project and availability. Additional data can be added if desired.

Customs regulations

The valid customs procedure including prior regulations, MRNs, HS code, country of origin, country of origin and customs value are registered within Babeldat. Therefore, the required data is always transparent.

Dangerous goods

When working with dangerous goods, inspection of the goods in the warehouse is important. Babeldat has an extensive ADR database, which can be supplemented according to your own requirements.

Flexible automated or manual invoicing.

An essential aspect of a Warehouse Management System (WMS) for logistics service providers is invoicing. Babeldat offers the option to compile invoices automatically or manually based on flexibly adjustable rate models. Whether it concerns order quantities or order lines, a suitable solution is available within Babeldat. This functionality extends to inbound, outbound, Value Added Services (VAS), storage and specific activities that are invoiced on an hourly basis.

Invoices are generated directly from Babeldat and their layout can be completely customized to your own requirements. Once the invoice has been printed or emailed, journal entries can be exported to your accounting package. We have extensive experience with various accounting packages, including ExactOnline, Unit4, SAP, Afas and Snelstart.

Control and Management from a handheld device.

The Babeldat WMS Android app is easy to download, allowing users to utilize their phones to attach photos to orders or products in the warehouse, or for instance, to photograph a packing slip during the unloading of a shipment. This way, the client gains immediate insights during the unloading process.

For barcode scanning, a device with a built-in scanner, such as those from Zebra, Honeywell, or Unitech, is recommended. Thanks to the Android application, all necessary information is always at hand. The Babeldat WMS App provides functionalities for inbound and outbound logistics, internal product transfers, inventory counting, and querying information about carriers, products, or locations. An additional advantage of modern devices is their 4G/5G capability, eliminating the need for Wi-Fi connectivity throughout the entire warehouse. This makes the WMS application on mobile devices extremely flexible and scalable.

Inbound

Checking and processing inbound orders.

Outbound

Order picking without paper.

Translocation

Perform internal warehouse movements for traceability of the goods.

Info

Additional information about warehouse locations, items, load carriers, etc.